Posted: 1st March 2023

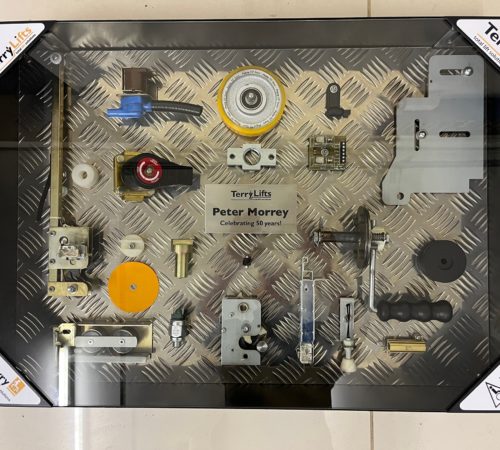

Chairman and owner of Terry Lifts, Peter Morrey is celebrating more than 50 years at the top of the thriving Cheshire-based manufacturing business.

Over five decades Peter has been instrumental in developing the business, overseeing its expansion from a small engineering firm to global access solutions provider, and improving the lives of thousands of people in their homes and public places.

Peter joined the business in 1972 as general manager, and after a small investment in his first year went on to acquire 100 per cent of the business over the next eight years or so.

“At the beginning I had to run the whole show, from product design, R&D, sales and surveys, installation, servicing, production, purchasing, factory maintenance, HR, health and safety, and feeding the works cat,” says, Peter Morrey, chairman and owner of Terry Lifts.

“When I arrived, the company had installed around 50 stair lifts and through floor lifts, but they were very basic and relied heavily on the user operating them correctly. My task was to add refinements and mechanisms such as locking devices, safety gear and interlocks to make the product safe to use – quite tricky when everything must be done mechanically rather than just fitting a switch.

“Alongside the hand-operated, counterbalanced lift we also designed a unique air operated step lift in 1974. I got the idea after reading an article on aircraft being recovered from runway overshoot using airbags and built the first prototype lift using a second-hand vacuum cleaner and a bin liner.”

The company went on to manufacture thousands of air operated Terry Step Lifts until the drive system was changed to hydraulic in 1998. Owing to the rise of electrically driven (rope driven) domestic through floor lifts in the late eighties, demand for the hand wound product started to decline and the company realised that change was needed to compete.

However, there was no challenge in producing an ‘also-ran’, so a direct acting hydraulic drive system was adopted. It was the launch of the Harmony in 1988 which set the company’s trajectory and remains a significant milestone for the business.

“The Harmony was a real game-changer for Terry Lifts,” says, Peter. “It was the first of its kind and has gone on to become a global best-seller. Benefitting from upgrades and developments over the years, the Harmony is still our most popular product.”

As an engineer, Peter’s main interest lies in problem solving.

“Product design and development has always been my focus, working on the basis that ‘build a better mousetrap, and the world will beat a path to your door’.”

This passion has led the company to design and launch a variety of successful and industry-respected lift products. For example, the ‘classic’ screw driven Melody 2 platform lift was introduced in the early 1990s and was superseded by the hydraulic Melody 2 in 2010, and then the Melody 3 in 2014. A special heavy duty step lift, TSL 1100 was created for the Australian market in 2011.

Most significantly, the Lifestyle home lift was launched in 2012. This compact fully enclosed two-person domestic lift enabled the company to extend its reach beyond its traditional customer base. Today, this lift is enjoyed by people of all ages and abilities across the globe. The Harmony range also received a boost with the introduction of a fully enclosed version, the Harmony FE in 2017.

In 2023, Terry Lifts is run by Managing Director Dave Allen. At 75, Peter was very happy to move on to the role of chairman and he handed over to Dave in 2020.

“I have been very privileged and proud to have headed up the company for the last 50 years and to see it grow into the successful business that it is today.

“I have had an incredibly rewarding career, with lots of fun and job satisfaction. The lifts we have produced have improved the lives of over 50,000 people.

“A business’s biggest asset is its employees, and its success is down to them. I am proud to say that we have had some incredible, loyal and long-serving people over the years but never better than the team we have today.

“Also, my wife, Sarah has worked in the business with me for 25 years, and she is instrumental. I’ve been the chief engineer – the guy who does the concepts, but it’s everyone else who takes that to fruition. A real team effort. My sincere thanks go out to our customers, management team and staff.”

This is an extract from an exclusive article which first appeared in Elevator World UK magazine.

*Parts and Labour

Proudly Designed and

Manufactured in Britain

Member of LEIA (Lifts

& Escalator Industry Association)

Notifications